| Nanotech Kit Part Number | Quantity |

|---|

| Additional Differential Mode Chokes Part Number | Quantity |

|---|

A variable frequency drive (VFD) is a motor controller that provides power with variable frequency and voltage, making it possible to control and change the speed of a motor. Power from a VFD is pulsed, which results in noise in the signal. This noise can lead to signal distortion, overheating, lubrication breakdown, EDM damage to motor bearings, and EMI radiation, which contributes to downtime and loss of productivity.

Get Permanent Protection From Downtime and Loss of Productivity

Traditionally, shaft grounding rings are used to minimize or eliminate electrical noise. An innovative alternative is MH&W’s nanocrystalline inductive absorbers, which suppress noise at the source, right at the VFD.

MH&W is a leader in innovative electrical noise-filtering solutions. We developed nanotech absorbers in kit form for easy installation, zero maintenance, and years of cost-effective protection.

Learn how to protect VFD motor systems from disruptive and damaging noise with our nanotech absorber kits.

What Is Nanotech?

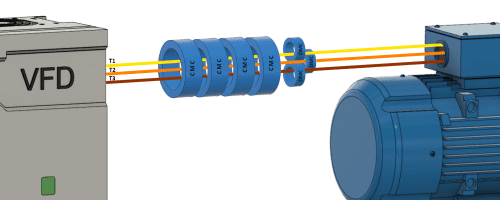

MH&W has developed a kit with Common mode and Differential mode chokes that absorb electrical noise. Noise is suppressed at its source — the VFD unit — so it never has a chance to reach the motor. The material that we use is highly effective at noise mitigation, so that fewer are needed for each application. This makes them a space- and cost-efficient solution.

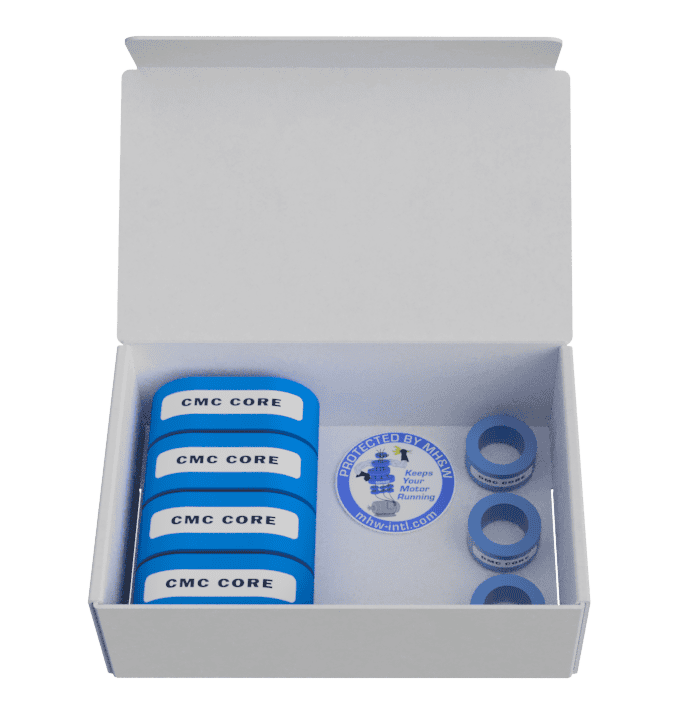

Absorbers are available in convenient kits with all of the components needed to mitigate undesired noise based on VFD horsepower and cable length, not motor size. They are designed for use in common mode choke (CMC) and differential mode choke (DMC) applications.

All absorbers are enclosed in a durable plastic casing for protection in any environment. As a result, you can use them indoors, outdoors, and in washdown settings. What’s more, only one kit is needed per system. This means there is no need to reinstall or replace them when a motor is serviced, as is required with rings, because the absorbers are not near the individual motors.

MH&W Nanotech Kits

- The MH&W Nanotech Kit solutions have already saved millions of $$ in the world’s industrial plants, hospitals, and office buildings by avoiding down time and equipment failures.

- Now available as standard kits for all HP ranges and cable lengths.

- Each kit comes with the appropriate size and number of Nanotech cores based upon HP rating of the VFD and length of power cable between drive and motor.

- Each CMC core comes along with a thermal temp dot on each core for over temperature monitoring.

- Each kit also includes full installation instructions and a Nanotech sticker.

CMC & DMC Applications

Common mode and Differential mode chokes made of nanocrystalline material suppress unwanted frequencies before they can reach the motor and are effective for both common mode and differential mode noise. They function as CMC or DMC, as follows:

- Common mode noise occurs when current on two or more signal lines flows in the same direction and returns on one common ground line. The CMC is placed around all of the lines and generates an equal and opposite magnetic field to filter our undesired frequencies.

- Differential mode noise occurs when current flows in one direction on a signal line and the opposite way on a return ground line. The DMC is placed on a single signal line to further reduce noise. It can be used in conjunction with a CMC.

Some of the most common applications of CMCs include the following:

- Electronics

- Industrial systems and machinery

- Light-emitting diodes (LEDs)

- Medical equipment

- Switch-mode power supplies for commercial or industrial applications

- Telecommunication systems

- Train signaling systems

Controlling electrical noise is critical in applications where failure is simply not an option, including transportation, telecommunication, and medical settings. It is also important for ensuring reliable electronic devices, lighting, and switching performance. As for DMCs, in conjunction with CMC’s, the goal of differential mode inductors is to decrease high-frequency AC current within circuitry even further in VFD motor systems.

Our absorbers are available in a range of kits based on VFD HP and cable length, which means it is easy to select the right setup for your needs. They are designed to aid in compliance with regulatory requirements and Federal Communications Commission (FCC) guidelines.

Applications Include:

- Electric vehicles (EV)

- Automotive manufacturing

- Agriculture

- OEM manufacturers of HVAC equipment

- Hospital/commercial/office buildings chillers

- All international VFD manufacturers

- Wind, solar, and other renewable energies

- All types of pumps and fans

- Paper/bottling/food/chemical manufacturing

NANOTECH KIT SELECTION GUIDE

| VFD SIZE | Cable Length (ft) 1 - 150 | Cable Length (ft) 151 - 300 | Cable Length (ft) 301 - 450 | Cable Length (ft) 451+ |

|---|---|---|---|---|

| UP TO 1HP | OKIT.0-1HP-150 | OKIT.0-1HP-300 | OKIT.0-1HP-450 | OKIT.0-1HP-451+ |

| 1.1 - 10HP | OKIT1.1-10HP-150 | OKIT1.1-10HP-300 | OKIT1.1-10HP-450 | OKIT1.1-10HP-451+ |

| 11 - 40HP | OKIT11-40HP-150 | OKIT11-40HP-300 | OKIT11-40HP-450 | OKIT11-40HP-451+ |

| 41 - 50HP | OKIT41-50HP-150 | OKIT41-50HP-300 | OKIT41-50HP-450 | OKIT41-50HP-451+ |

| 51 - 100HP | OKIT51-100HP-150 | OKIT51-100HP-300 | OKIT51-100HP-450 | OKIT51-100HP-451+ |

| 101 - 428HP | OKIT101-428HP-150 | OKIT101-428HP-300 | OKIT101-428HP-450 | OKIT101-428HP-451+ |

| 429 - 1631HP | RKIT429-1631HP-150 | RKIT429-1631HP-300 | RKIT429-1631HP-450 | RKIT429-1631HP-451+ |

| 1632HP+ | OKIT1632+HP-150 | OKIT1632+HP-300 | OKIT1632+HP-450 | OKIT1632+HP-451+ |

Notes:

- Kits are based on VFD size, not motor size.

- Kits are based upon one cable (one conductor per phase) between VFD and motor.

- If multiple cables are used between the VFD and motor, contact MH&W Engineering or Sales to determine the necessary DMC core add-on pack needed.

- A complete installation guide is included in the kit.

- All cables/phases must travel through the CMC cores.

- DMC cores are per phase.

- No grounding wires, armored or shielded cables can go through any cores!

- On motors 10HP and below, two turns are needed through the CMC cores. More information on this is in the installation guide.

- It is important to use the correct kit for each application.

- Install cores on the load side of the VFD for typical motor applications, temp dot visible.

- Brackets and additional cable ties are available from MH&W to help hold cores in place, if needed.

- Kits are applicable for servo and DC motors too. Call MH&W Engineering for more information.

- All kits are available in round (R) and oval (O) configurations.

Common Mode & Differential Mode Noise Solutions From MH&W Nanotech

VFD motor systems are useful for a wide range of industries and applications, but they are all vulnerable to electrical noise that is disruptive and potentially damaging. An innovative alternative to traditional grounding rings is MH&W’s Filter Solutions. Available in convenient kits, they are a cost-effective and reliable way to control noise and protect equipment.

Contact us to learn more about nanotech kits, or request a quote for your application.