5 Tips for Reducing Electromagnetic Interference (EMI) in VFDs

Variable frequency drives (VFDs) are widely used in industrial applications to control the speed, start-up, and torque requirements of electric motors. However, VFDs can produce electromagnetic interference (EMI) that can cause problems with other electronic equipment in the vicinity.

Electromagnetic interference, called EMI, is unwanted electrical noise that prevents electronic systems from performing as intended. EMI occurs when an electromagnetic field causes disruptions in the radio frequency spectrum of a communication, analog, or digital electronic system. Since EMI can cause devices to operate poorly and, in some cases, to stop working completely, learning how to reduce electromagnetic interference is very important.

As industry experts with over 50 years of experience, MH&W International Corp. offers reliable solutions for reducing electromagnetic interference in variable-frequency drive systems (VFDs). While our choke products provide a simple and cost-effective method of eliminating high-frequency noise, there are other steps you can take to reduce EMI.

Here are five tips for reducing EMI in VFDs:

- Proper grounding: Proper grounding is essential for reducing EMI. Ensure that the system’s VFD and all other electrical equipment are properly grounded according to local codes and standards. One of the first steps to reduce EMI is to properly ground the VFD and other components. Since high-frequency EMI travels on a conductor’s surface, selecting a braided conductor provides increased surface area and a lower resistance path for noise to travel to the ground. Instead of using a solid conductor, consider a multi-strand option.

- Shielding: Shielding can help reduce EMI from VFDs. Use shielded cables for power and signal connections and ensure the shields are grounded properly.

- Proper wiring: Proper wiring can reduce EMI. Keep the wiring as short as possible and avoid running it parallel to other wiring or metal surfaces. Use twisted pair wiring for control signals. Shielded cables effectively minimize the effect of capacitively coupled EMI between two cables that run parallel to one another. To accomplish this, the shielding must be grounded only at one point: at the noise source or the panel. However, for high-frequency noises above 1 MHz, it’s better to ground the shield at both ends. This method is also applicable to analog cables. High-power DC voltage cables, motor cables, and other lines should be spaced out by at least eight inches when placed parallel to prevent high-frequency couplings. Taking this precaution will be very helpful in preventing signals from coupling with one another and generating noise.

- Filtering: Filtering can help reduce EMI. Install filters on the input and output of the VFD to suppress the high-frequency noise. If EMI generation is unavoidable, the next best step is mitigating it at the source or preventing it from entering the system. To achieve this, mount AC line filters on either the grounded frames or the backplane during the design phase. This will prevent EMI from entering the system.

Since input line side cables also produce noise, minimize it by routing input power cables as far as possible from output power cables and other cables in the circuit. Additionally, the AC power’s length should be reduced, and the filter should be properly grounded and installed near the source of EMI.

- Distance: Increasing the distance between the VFD and other electronic equipment can also help reduce EMI. If possible, locate the VFD in a separate enclosure or room.

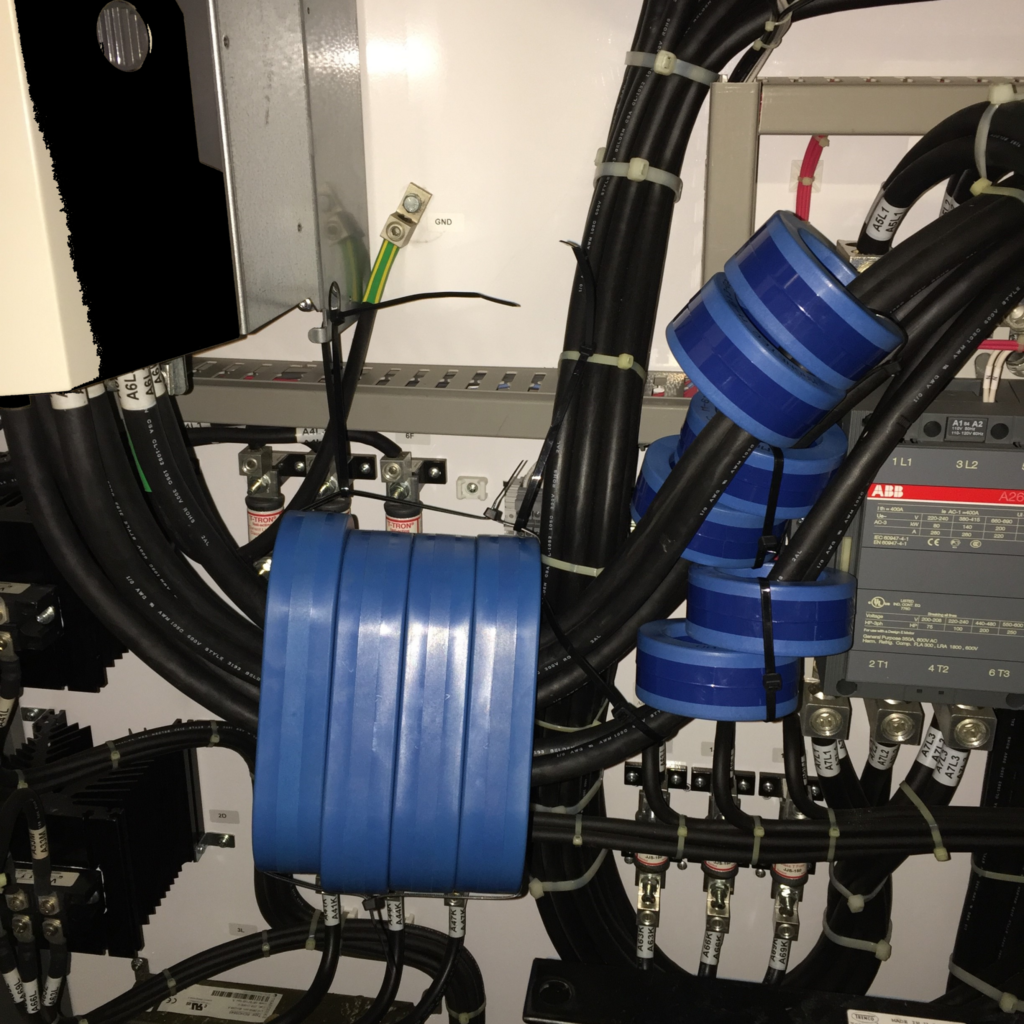

Install Nanotech® Cores at the Inverter Output

Out of all the previously discussed methods for reducing EMI, proper wiring is the most effective method; if combined with Nanotech® cores, it is the most simple and effective solution. MH&W Nanotech® products are common mode toroidal cores made with nanocrystalline material that eliminates high-frequency noise at the source.

Our Nanotech® cores are so effective that unshielded cables can replace shielded cables, reducing the system’s overall cost. Other key benefits of Nanotech® cores include:

- Effectively reduces radiated emissions

- Maintenance-free

- Long service life

- Easy to install and compatible with existing drive setups

- Highly effective in drive systems with long cable runs

The Nanotech®’s magnetic core captures and absorbs high-frequency currents, eliminating unwanted noise. These products are very beneficial in conducted or radiated EMI applications and unlike filters, Nanotech® cores have no passive elements, resulting in low losses.

Why Choose MH&W

Reducing electromagnetic interference is critical for any type of VFD. While there are many steps you can take to protect your equipment, installing Nanotech® cores is the most effective and long-lasting solution. MH&W specializes in providing innovative technology for VFD motor installations. Our products are used globally by major OEM VFD manufacturers and end users to ensure their equipment properly functions.

With engineering and sales operations throughout the U.S., Mexico, and Canada, MH&W International supports the power supply and telecommunications industries with thermal interface materials, powder cores, and other products and services that promote our customers’ long-term goals.

MH&W International is a leading supplier of magnetic components with over 55 years of experience in the industry. Here are some reasons why you may choose MH&W:

- Quality: MH&W only sources materials and components from reputable manufacturers to ensure consistent product quality. We also have rigorous quality control processes to ensure that all products meet or exceed customer expectations.

- Technical expertise: MH&W has a team of experienced engineers knowledgeable in magnetic materials and their applications. We can provide technical support to customers and help them select the best products.

- Customization: MH&W offers customization services to tailor standard products to customers’ requirements. We can modify products such as cores to meet unique specifications.

- Global reach: MH&W has a global reach, with sales and distribution centers in North America, Europe, and Asia. This allows us to serve customers worldwide and provide local support in different regions.

- Competitive pricing: MH&W strives to offer competitive pricing while maintaining high-quality standards. We have long-standing relationships with our suppliers, allowing them to negotiate favorable pricing for our customers.

Overall, MH&W is a reliable supplier of magnetic components with a strong commitment to quality, technical expertise, customization, global reach, and competitive pricing.

We offer a comprehensive range of choke products, including:

- Common Mode Chokes (Single Turn) for Protection of Generator/Motor Bearings

- Magnetic Materials for Common Mode Chokes in the Inverter Circuit

- Magnetic Materials for Smoothing Chokes in the Inverter Circuit

- Magnetic Materials for Solar Panel Common Mode Choke

- Magnetic Materials for Smoothing Choke (Inductor)

- Smoothing Chokes

To permanently resolve your EMI and VFD motor problems, contact our team today.